Stress Test

By Patrick Wagner

Colorado Leaf owners Keith and Brett Sprau woke up one morning in November to an unexpected six inches of fresh white powder covering their commercial greenhouse, including their newly added 488 cannabis plants.

“Everything they warn you about in the beginning to be careful with — it all happened within the first four days of this greenhouse being up and running,” Keith said.

The Colorado Leaf grow facility sits roughly a football field’s length away from the base of the Rocky Mountains. The Sprau brothers and head grower Victor Moran all live onsite, giving them quick access to the greenhouse in the case of an emergency, such as they experienced with the first blast of winter.

All three have witnessed dire weather predictions that never came to fruition. They’ve often watched the forecasted weather pummel the slopes of the Rockies across the street without a drop of rain or snow touching their property.

But this mini-storm caught the team unawares.

The early snowfall froze the gutters and blanketed the roof, but it didn’t block access to the greenhouse.

Brett and Keith both joke about Victor being the company contingency plan, but that November morning he was the first to respond. Victor’s first priority was to check the generators to make sure they were topped off with diesel. Next, he reviewed the environmental control log with the hope of determining exactly when the snowfall had hit while they were sleeping only 200 yards away.

The team pushed through the unexpected snow, checking every few hours on the generators and temperatures until the threat of large-scale crop loss had melted away just days later.

“Everything worked great,” Victor said of the greenhouse and environmental control systems in place.

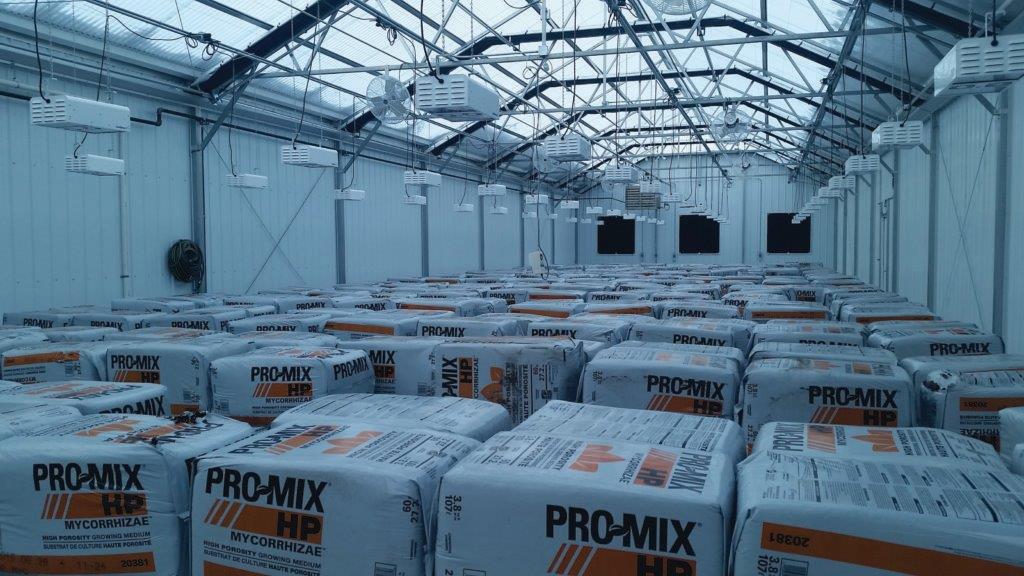

Phase one of the Nexus greenhouse construction has been completed, and the end of phase two is within sight. But before the team can focus solely on the 488 plants in the veg house, they’ll need to oversee the final stages of work from the contractors. Colorado Leaf needs to finish installing the last of the computers and software systems, and the company’s standard operating procedures still need to be written.

The 20,000-square-foot facility’s standard operating procedures are being penned by the three men as they simultaneously coordinate with the remaining contractors and state inspectors, nurture the plants during early growth stages, and wrestle with snowballs Mother Nature likes to throw every once in a while.

Victor has been working to establish a consistent atmosphere for the plants via the environmental controls. He is also setting up ancillary systems that will help streamline the new control systems.

“We’ve got all the state systems up that we’re required to have, but we are getting a couple of extra ones that are going to make our lives a little easier,” Keith said. “Not easier, but more efficient is what it boils down to.”

The extra layer of controls will work with tablets and wireless scanners to remove several steps from Colorado Leaf’s daily operations. These systems will automate certain greenhouse maintenance tasks that are tedious but paramount to the operation. For Victor, chores like feeding the plants can be reduced to simply pulling a trigger.

“We can go in and batch our plants, scan them and feed them,” Victor said. “By literally scanning three things we can feed an entire house.”

Brett has been handling the finances, marketing, sales, and all other clerical aspects of the operation. Meanwhile, Keith has been refining each daily, weekly and monthly process into a readable standard operating procedure and coordinating with the last of the contractors.

The Sprau brothers admit to not being the “most tech-savvy guys” and without reliable cell phone service at their head house they cannot rely on having an IT specialist talk them through troubleshooting. The bandwidth has also proven to be too slow for specialists to fix problems by remote access. The restrictions have forced the brothers to cover what technical gaps they can and hire yet another IT contractor to tackle the remaining problems.

“So that’s been a big thing but once we get the logistics and computer service up and running down there we’ll be fine,” Keith said.

GREEN AT THE END OF THE TUNNEL

After Keith, Brett and Victor establish their standard operating procedures and see the final crop of contractors through the door, they can focus on populating the grow. Victor will use the original 488 plants to build out the plant count to the state allowed limit of 3,600.

“When we wake up in the morning, all three of us, the only thing that will be on our minds is the plants,” Keith said. “So basically that next stage is getting these plants healthy and big, then cutting them down and then getting them heathy and big. Then we can actually get into a cyclical action of clones, veg, flower, harvesting, selling and getting it all back.”

“We’ll put out the ones that we know are really good, that Vic is very, very comfortable with growing commercially,” Brett added. “Just so we can get a consistent top-quality product out there.”

In the meantime, Brett will be focusing on grassroots marketing, sales and scheduling limited releases for the OG strains. Colorado Leaf is hoping to have the “artisan” strains ready for 4/20, with another limited release slated for Christmas of 2016. The timing could be perfect as Colorado has recently seen an unprecedented spike in wholesale prices.

At one point, wholesale cultivators like the Spraus had already spent the past year expecting a price drop. As growers prepared to fight over precious 2016 shelf space, the market did the complete opposite.

“We don’t know why,” Brett said. “But it (the wholesale price) jumped from $1,800 per pound to almost $3,000. So the demand has become really high for wholesale rec right now in Colorado.”

Having survived the first threat of winter and seeing the new surge in wholesale prices, the Sprau brothers have reluctantly started to feel optimistic for the future of Colorado Leaf.

“We got all of the crazy extremes, hopefully, taken care of right when we started,” Brett said. “We’ll see how the rest of the winter goes.”