The sun sets over Canndescent’s non-descript cultivation facility in Desert Hot Springs, California. Photo courtesy of Canndescent.

As the Golden State begins its transition into a legal, adult-use marijuana market, more and more corporations and investors will begin opening large-scale growing and processing facilities, and companies with the vision and motivation to start on these ventures early will have a decided edge. One such company is Canndescent, which opened Southern California’s first government-sanctioned cannabis factory in Desert Hot Springs two months before Proposition 64 was approved by voters.

This state-of-the-art facility is emblematic of the new, legitimate face of cannabis, as evidenced by its grand opening ceremony in September. The event commenced with the Pledge of Allegiance, led by a local Boy Scout troop, followed by a ribbon-cutting ceremony and a speech by Mayor Scott Matas, who voiced his support for the venture in no uncertain terms.

The wives of the Canndescent founders participate in the ribbon-cutting ceremony at the grand opening of the facility. Photo courtesy of Canndescent.

“Recently, I had a gentleman come up to me and say, ‘How can you do this morally?’” Matas told the crowd. “And I said, ‘Really? Whether I was for it or against it at one point, that means nothing. As the leader of Desert Hot Springs, I have to lead the effort. Over the next five to 10 years, this can help us see the tax revenues that can really take this city to the next stage — to clean up our roads, gutters and medians and make the city beautiful. And I’ll tell you: Morally, I’m good with it.’”

The ceremony concluded with Matas unveiling a historical marker with a plaque that reads: “This marks the site of the first municipally permitted cannabis cultivation site in California. On October 21, 2014 Desert Hot Springs became the first city in California to legalize cannabis cultivation. On September 19, 2016 Canndescent commenced production.”

Canndescent CEO Adrian Sedlin, who has an MBA from Harvard, came out of retirement in 2015 to co-found Canndescent with his brother-in-law, Randy Patten — a long-time cannabis grower who now holds the title of chief cultivation officer.

Prior to the ceremony, Sedlin personally guided members of the press through a private tour of the property, proudly listing its specs. The facility consists of two main buildings, each 60 feet by 80 feet for a total space of 10,400 square feet. The buildings require 2,000 amps of power, about 20 miles of wiring, five miles of Ethernet cable and 160 tons of cooling power, all of which was built and installed in less than six months by partners Brad Wilson and Chad Spooner.

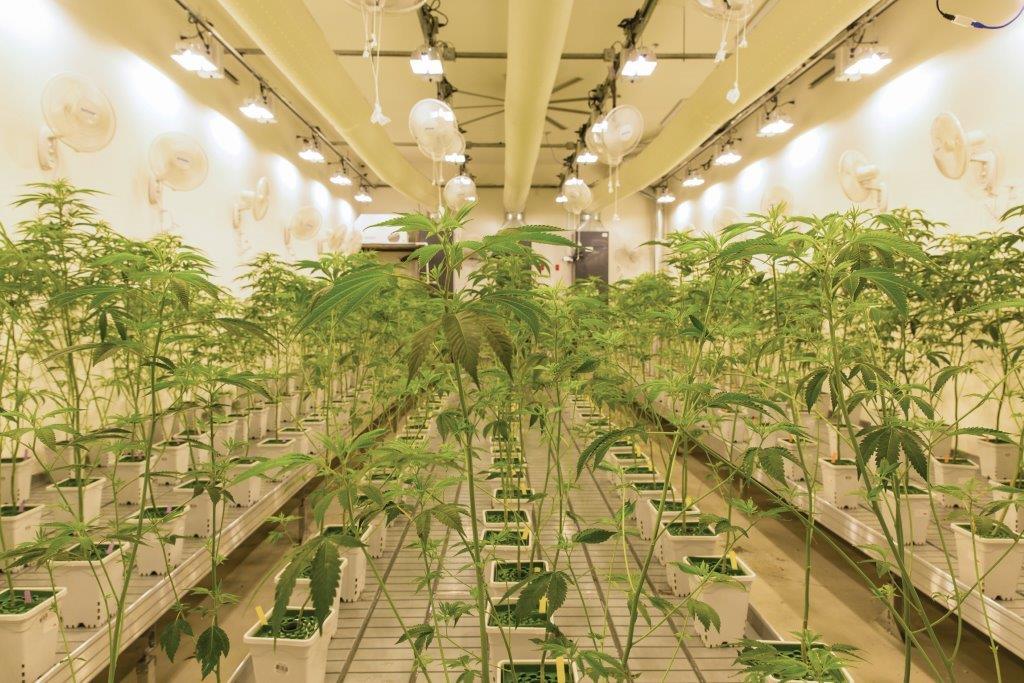

Each of the Canndescent buildings contain 20 miles of wiring, five miles of Ethernet cable and 160 tons of cooling power. Photo courtesy of Canndescent.

Each building contains three rooms for flowering, one for vegetation and mothers, two for drying and one for trimming. Each grow room is fed by its own 2,500-gallon water tank and fertigation system that cools the water and automatically adds the appropriate nutrient mixture for the stage of the growth cycle. A reverse osmosis system removes minerals from the water, and ultraviolet radiation kills all bacteria, bio-organisms and viruses. The rooms contain a total of 250 lights, including green lights for when employees are working during the day. For ventilation, they utilize a series of Solenoid valves providing CO2 every six feet and Big Ass ceiling fans to eliminate any hot spots by pulling hot air up and away from the plants. The temperature, humidity and CO2 levels inside each room are continually monitored and displayed in real time on flatscreens just outside the doorway. All that information flows directly into a database and is analyzed to determine any necessary adjustments. Rolling benches allow workers to slide the grow tables back and forth to create aisles where needed to maximize the space, which Sedlin claims increases yield by about 40%.

On average, each of flower room blooms every 60 days. Taking into account the two buildings and the rotational planting schedule, that translates to a harvest every 10 days — which works out to a total production capacity of 2,500-2,700 pounds a year.

A garden attendant waters plants, while water-mats keep excess waste to a minimum. Photo by Inae Bloom.

Following each harvest, the crop is moved into the drying room and the grow rooms are cleaned and sterilized. The harvested crop is slow dried for 14-20 days, depending on the strain, then cured for another 14 days in tubs. Eventually, Sedlin says, the company plans to install an automated overhead racking system much like the ones common at dry cleaners, which should serve the dual purpose of optimizing revenue and improving the quality of life for the company’s employees.

Each trimmer is provided with jewelers loupes, ergonomic chairs and adjustable-height tables. Working in six-hour shifts, they process the crops under the strictest of guidelines. First, the weight of the product is logged going into the room. Next, the team meticulously manicures the raw plants into usable material using a technique where they only hold the stem.

“Our philosophy is, ‘Thou shalt not touch the flower,’” Sedlin explains. “No employee is ever permitted to touch the flower. If you’ve ever held really good cannabis, it’s sticky. Well that sticky is the resins, and that’s the consumers’ property — that’s not ours. We want all of those loose resins with all their great terpene profiles imbued into the product.”

Green lights allow maintenance to continue without interrupting the plant’s day/night schedule. Photo by Inae Bloom.

When the trimmers have completed their job, the processed material is divided into three piles: waste, which is sold for fiber and industrial uses; fine trim, which is used for extraction; and of course, finished flower. Added together, the three piles must add up to the initial weigh-in.

“Our strategic objective is to produce ultra-premium flower — the top-shelf boutique stuff that connoisseurs appreciate,” Sedlin says.

He claims all the company’s product has a unique, iridescent shimmer.

“That’s actually where the name of our company comes from — iridescent, meaning to project light,” he says. “That’s really what Canndescent is about — spreading light.”

The company also rejects the common nomenclature of the cannabis industry.

“We don’t believe in strain names,” Sedlin says. “We think it’s an antiquated model for the industry. Companies like Leafly try to explain cannabis through a periodic table of 6,000 strain names. Well, I hated the periodic table in fifth grade, and I hate it even more now. You shouldn’t have to be a weed scientist to figure out your cannabis selection. We’re trying to really simplify it.”

To that end, rather than naming strains based on lineage as most breeders do, Canndescent names them after how they supposedly make users feel.

The innovative grow room design at Canndescent allows the company to pull a harvest every 10 days. Photo by Inae Bloom.

“We market all of our products under what we call our five pillars: Calm, Cruise, Connect, Create and Charge. To use a BMW analogy, every product series in the pillar has a number to it: Calm is the 100 series; Cruise is the 200 series, etc. So if you want to go play volleyball, you know to hit some Charge. If you’re going to a dinner party or a more amorous setting, that’s when you’d reach for Connect.”

Once processing is complete, the finished product is stored inside a 12-hour-rated bank vault until it’s ready for transport. The vault doubles as a panic room for the employees in case of a robbery or other emergency. Every inch of the facility is monitored by 64 12-megapixel cameras, whose live feed is uploaded to an encrypted IP address that police can access 24 hours a day. In addition, all entrances and exits are outfitted with motion and vibration sensors and authentication requirements.

While the company has spared no expense in safeguarding its product, Sedlin says protecting the brand’s integrity is just as valuable.

“What our company wants to stands for is the pursuit of personal excellence,” he says. “It’s about extraordinarily hard work, personal drive, deep integrity and a huge sense of gratitude for the blessings we all enjoy in this world.”

Adrian Sedlin demonstrates the standard for Canndescent’s trimming techniques. Photo by Inae Bloom.

Sedlin also expressed his gratitude in several ways during the company’s grand opening ceremony: paying off the remainder of those Boy Scouts’ GoFundMe campaign, rewarding partners Wilson and Spooner with all-expense paid vacations, and treating everyone in attendance to a lavish after-party at the local spa. For Sedlin, it’s all part of changing the mainstream’s perception of marijuana and the people who enjoy it.

“Our goal as a company is to help cannabis cross over, make it a consumer accessible product,” he states. “I’ll know my job is done when, instead of people bringing a bottle of wine to a house party, they gift carafes of cannabis and there’s a cheese board of cannabis right next to the bar.”

[contextly_auto_sidebar]